Selective Plating

Hudson Plating Works has an extensive, highly experienced and creative masking department to meet your most demanding selective plating needs. When the blueprint specifies this requirement you can count on our Nadcap Certified facility to properly interpret your drawing and meet the requirement to the letter.

How Is It Done?

First, what is selective plating? It’s a method of electroplating a specific material such as nickel, copper, gold, silver, or tin onto a selected surface of the part without plating the entire part. This process is many times used for repairing mis-machined or worn machine parts. It’s also used as a tool for applying plating materials for surface modification, per blue print specifications, or engineering instructions.

Each job is unique and requires careful determination of the selective plating directive. The correct masking is critical and many times close tolerances must be maintained. A variety of masking materials are available and customized masking techniques are utilized at Hudson Plating Works.

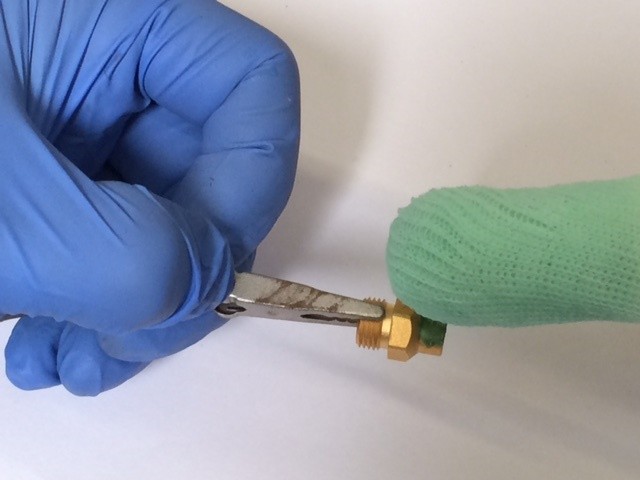

If the part is an assembled piece, perhaps it cannot be immersed in the solutions and baths necessary for electroplating. This is where “brush plating” is a convenient method to achieve the selective plating that is needed. The process is accomplished with the use of an anodic dalic that is impregnated with the metallic solution, nickel, copper, gold, silver, or tin and “brushed” onto the prepared surface of the part. The thickness of the plating is achieved with careful calculation and applied current. The end result is the selective plating applied only to the specified area of the assembled part.

As you see, selective plating is a specialized process with demanding requirements. Hudson Plating Works has years of service in successfully achieving the most exacting selective plating assignments. Let us handle your most intricate selective plating needs.