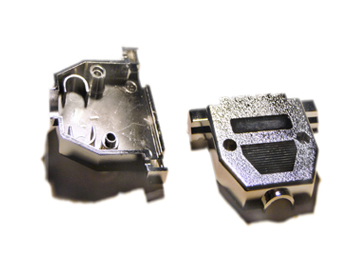

Tin Plating & Tin Lead plating

We offer many variations of tin plating in accordance with MIL-T-10727, ASTM B545, AMS-2408, MIL-P-81728 as well as other industry and customer specific specifications.

- Pure Tin (Bright finish)

- 90% Tin 10% Lead (Bright finish)

- 60% Tin 40% Lead (Dull finish)

Hudson Plating Works provides quality functional bright and matte (solderable) tin plating in accordance with MIL-T-10727 and ASTM B545, AMS-2408, MIL-P-81728 as well as other industry and customer specific specifications. Our expertise in providing precision barrel or rack bright and matte tin and tin alloy plating is employed in numerous industries including the electronic, telecommunication, aerospace industries.

Tin is a soft, ductile, silvery-white metal that is not easily oxidized in air. It has good conductivity and corrosion resistance while enhancing solderability of substrates that are not otherwise easily soldered to.

Hudson Plating Works has the expertise in tin and tin alloy plating services to ensure proper functionality of the deposit including maximizing solderability for solderable applications.

A suitable underplate with copper or nickel plating will enhance the durability or solderability of tin plating applications.

Tin deposits can have the potential to form filiform tin whiskers that propagate from the surface of the deposit. For applications where tin whiskers could negatively impact the function of the product, Hudson Plating recommends a tin-lead plating application that is immune to the potential for whisker growth. We offer both 90/10 or 60/40 alloy tin-lead processing.

All analytical and testing compliance is performed by the HPW in-house laboratory. Thickness and adhesion verification, solution analysis, hydrogen embrittlement relief, as well as composition solderability and porosity testing are a sample of Tin & Tin/Lead plating specification requirements. Inspection and testing are completed and documented for assurance of compliance to all specification and customer requirements.